Coatings market faces complex landscape – brands predict antifoul trends for 2025

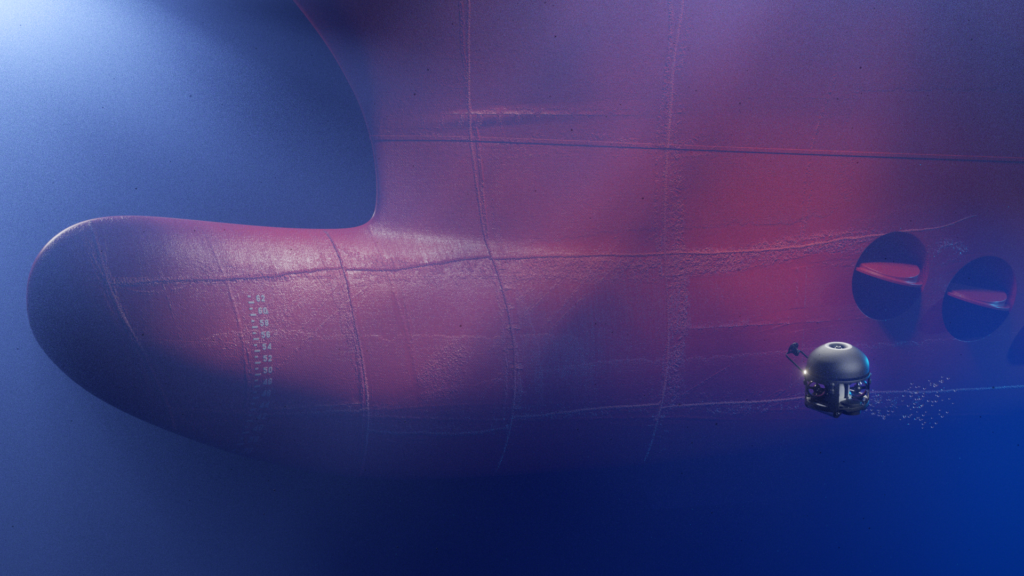

Marine Industry News sits down with Nippon Paint Marine and Propspeed to learn about the challenges which the marine coatings market faces in 2025, including antifoul trends. Stringent regulations, demands for more fuel savings, data validation and global supply chain problems are all in the mix, alongside continued innovation designed to satisfy consumer need – while taking the sector to a more sustainable future.

“Although the maritime sector faces significant challenges, the industry’s transition to more sustainable practices provides an opportunity to showcase the contribution that leading hull coatings can make in supporting the industry’s decarbonisation efforts, while remaining cost-effective,” says Kazuaki Masuda, corporate officer, technical division at Nippon Paint Marine.

Masuda (pictured) expects the coatings sector to face a complex landscape in 2025, with several challenges shaping the industry’s trajectory.

One of the most significant is the introduction of increasingly more stringent regulations. The challenge created by the current regulatory fragmentation means that shipowners must navigate varying compliance requirements, making it essential for them to adopt solutions that meet the highest regulatory standards, globally.

Furthermore, The IMO’s evolving frameworks, including stricter CII compliance requirements, are forcing shipowners and operators to engage with new green technologies to support emissions reduction and remain compliant. (Nippon Paint Marine has a biocide free self-polishing coating with details on its website.)

2025 sees intense market competition in marine coatings sector

“Market competition also continues to intensify, with shipowners demanding coatings that deliver enhanced fuel savings and extended performance while remaining commercially viable,” he says. “At the same time, the demand for operational data validation is increasing, requiring coatings manufacturers to provide regular performance assessments that align with international verification standards, such as ISO 19030 speed-loss evaluations.

“Global supply chain volatility remains a persistent challenge, affecting raw material availability and pricing. Ensuring stable production and delivery of high-performance coatings amid these fluctuations will be critical to maintaining customer confidence and meeting the industry’s operational needs.”

Biocide free coatings must perform AND protect environment

“The development of antifouling solutions and marine coatings is a process of continual innovation and investment in R&D; we must always strive to meet the ever-changing challenges of the industry, particularly in relation to supporting the drive for increased efficiency and sustainability,” Masuda continues.

“At Nippon Paint Marine, we are committed to advancing coatings technology to address the priorities of enhancing vessel performance whilst also supporting the industry’s decarbonisation efforts.”

Masuda says the company’s patented HydroSmoothXTTM technology exemplifies how it’s advancing the development of friction reduction in hull coatings, creating a smoother surface that delivers improved fuel efficiency and lowers emissions and associated costs.

“Furthermore, the industry is also seeing increasing interest in biocide-free self-polishing copolymer (SPC) coatings, which support regulatory compliance while maintaining high performance, as well as protecting the marine environment.

“The continued development of both hydrophilic and hydrogel-based coatings,” he says, “are emerging as promising solutions that greatly enhance fouling prevention.”

Meeting stringent regulations with continuous innovation

“As shipowners and operators look for ways to cut energy consumption and comply with more stringent regulations, coatings technology must also evolve. Customers are not only focused on immediate efficiency gains but also on the broader impact of their coating’s choices, reinforcing the need for continuous innovation.”

Masuda believes that shipowners and operators want coatings that deliver tangible cost savings as well as enhanced operational benefits. But that’s also while complying with tightening environmental regulations. “At the core of their requirements, are longer in-service performance, reduced maintenance costs, and fewer dry-docking intervals, which are all key factors that contribute to overall operational efficiency,” he says.

Propspeed’s CEO, Marcus Hamilton, agrees. He says that while legislation is one important driver, customer needs are at the core of innovation.

“Innovation for the sake of innovation does not create value for the industry—unless it is tied to addressing customer’s needs in a meaningful way,” Hamilton (pictured) explains.

“Customers’ needs can be driven by many things, legislation is one of them, but changing economic, environmental, and customer demographic forces all present opportunity for innovation. This is where strong relationships with distribution, OEM partners and end customers is important. The stronger the feedback loop between these stake holders the greater the opportunity for successful innovation.”

Fuel saving remains priority in 2025’s antifoul trends

Masuda says for Nippon’s customers, fuel saving remains a top priority, particularly as shipowners navigate the challenges of CII compliance and other emissions reduction regulations.

“High-performance coatings help mitigate hull fouling, which in turn reduces drag, optimises vessel speed, and lowers fuel consumption, emissions and costs,” he says. “In fact, our leading antifouling solutions have been found to achieve significant fuel savings of up to 14.7 per cent, compared to the market average.

“Independent validation of these benefits is also crucial, with shipowners increasingly looking for performance data that tangibly proves the impact that the coating technology is having on the vessel’s performance.”

Beyond technical performance, there is growing recognition of the role coatings play in reducing a vessel’s overall impact on the environment. Biocide-free and low-VOC coatings are gaining traction as shipowners look for sustainable solutions that align with both current and future regulatory expectations.

The post Coatings market faces complex landscape – brands predict antifoul trends for 2025 appeared first on Marine Industry News.